-

Intern to Full-Time Employee with Melanie Muncy

-

Employee Spotlight: Michelle Veale, Shaping the Future of Transportation at Ulteig

-

Disaster Recovery Planning: Safeguarding Our Water Lifeline

-

Ulteig Acquires Affinity Energy, Expanding SCADA Capabilities

-

RTOs and Potential Implications for the Future of Energy

-

Ulteig Named a 2024 Top Workplace by USA Today

-

Is Your Project Ready for MISO’s Interconnection Queue?

-

How to Know It’s Time to Repower Your Wind Farm

-

Ulteig Supports Girls in STEM through Nationwide Initiative

-

How Climate Change Can Affect Bridges and Bridge Inspections

-

Employee Spotlight: Chase Anderson, Project Manager

-

Where Utilities are Making Grid Modernization Reliable and Resilient

-

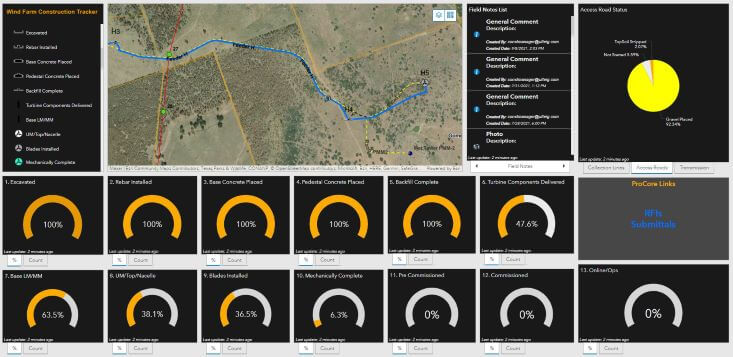

Pioneering with PinPoint™ and the Future of Project Management

-

How Ulteig Can Help You Comply with the July 1st Deadline with CAISO’s New Security Protocols

-

Ulteig Launches PathFinder™, Demonstrates Commitment to Innovative Technology Solutions

-

The Inflation Reduction Act (IRA): A New Dawn for Renewable Energy Self-Development in Utilities

-

Fostering the Future of Engineering: Ulteig’s Involvement with the RMEL Foundation

-

Safe Streets for All: Ulteig’s Approach to Enhancing Roadway Safety

-

Energy Solutions for Extreme Weather Conditions

-

The Path to Renewables Success: The Value of Owner’s Engineering

-

Celebrating & Honoring Veterans

-

Celebrating Diversity, Equity and Inclusion at Ulteig

-

Maintaining the Health and Longevity of Bridges

-

Grady Wolf joins Ulteig as an Associate Director – Environmental

-

New vs. Modernized Infrastructure: Which is the Path Forward?

-

Employee Spotlight with John Forman, Senior Engineer

-

Navigating Federal Policy for Clean Energy Development

-

Ulteig and CIPCO Celebrate Over 5 Decades of Innovation

-

Supporting the Future of Electric Vehicles

-

Ulteig Once Again Named to Prairie Business Magazine’s Best Places to Work

-

Humanity Rising Partnership: Investing in the Next Generation of Sustainability Leaders

-

Day of Understanding: Disability

-

Where Utilities Are Making Progress in the Future of Grid Modernization

-

Solving for the Future: Smart Work Zones

-

Ulteig Names Alison Barie as New Chief Financial Officer

-

Ulteig Announces Partnership with Engineers Without Borders USA (EWB-USA)

-

Ulteig Partners with LineVision

-

Staying In the Now: Emerging Energy Trends & Technologies

-

Ulteig Receives Multiple National Cultural Excellence Awards

-

Market Analysis & Homegrown Innovation

-

Day of Understanding – Gender

-

Welcome Myron Hora

-

Solving for the Future: Electric Vehicles

-

Revisiting Solar’s History to Predict Its Future

-

Nick Ingolfsland, CITO, Makes the Case for Internal Software Development

-

Women in Engineering Day 2023

-

Remaining Authentic in Our Inclusive Practices

-

Connect to Your Data With SiteSense

-

Sarah Beckman talks Valuability and Moving Beyond Basic Project Metrics

-

Ulteig Named a Top Workplace by Star Tribune for 2023

-

Ulteig Receives Top Marks from Leading Industry Lists

-

Ulteig Named to Zweig Group’s 2023 Hot Firms List

-

Ulteig DEI Program Leader Interview

-

John Butt Recognized as AEC Industry Rising Star

-

Denver Office Wins Top Workplace Award Once Again

-

Why Nuclear Energy is Experiencing Renewed Momentum

-

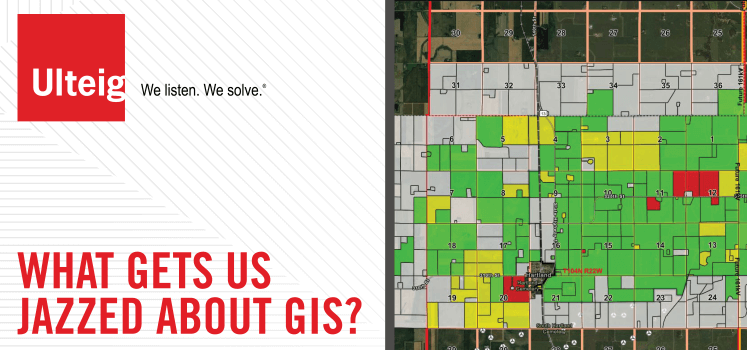

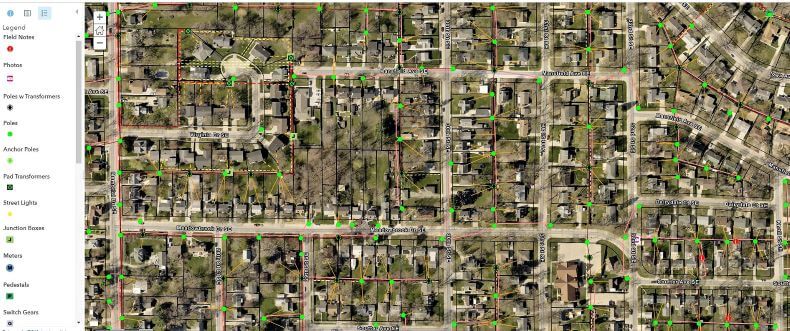

Ulteig GIS Technology Featured in RMEL Magazine

-

Jim Horn talks The Future of Work

-

Leadership Moment: Mckenzie Dickerman – Project Manager

-

Discussing Decentralized Grid Technologies with Sarah Beckman

-

Leadership Moment: Jesse Erickson, PE – Market Director – Key Client

-

RMEL Scholarship Opens Doors for Electrical Energy Students

-

WTS Colorado Honors Angy Casamento & CDOT I-70 Bridge Replacement

-

Ulteig Wins Two ACEC North Dakota Engineering Excellence Awards

-

The Keys to Clean Energy Resilience

-

Jen Turnbow Rejoins Ulteig in new role as Director of Business Operations

-

Eric Milliken, PE, PTOE, Presents Award-Winning Study

-

Aldo Lopez, PE – Engineering a Positive Community Impact in Texas

-

Jason Adams, PE – Designing a Safer Transportation System for Texas

-

Ulteig is #14 in US on Glassdoor’s Best Places to Work List

-

Kelly Bjerke Retires

-

Leadership Moment: Mike Huffington, Market Development Manager – Transportation and Environmental

-

How FERC Order 881 Will Impact Utilities

-

TJ Fakler on Prairie Business’s 2022 Top 40 Under 40

-

How Ulteig is Turning Our Understanding of Funding Into Success for Our Clients

-

Employee Spotlight with Mike Metcalf, PE – Technical Manager

-

Connecting Projects with People: Eric Barradale, PE on Growing a Power and Renewables Presence in the Southeast

-

Leadership Moment: Josh Potts, PE, Technical Manager – Transmission & Distribution

-

Employee Spotlight with Jeremy Veldhoen – Lead Systems Integrator

-

Ulteig Secures Multiple Awards from ACEC Colorado

-

Ulteig Receives Global Supplier Award from Bechtel

-

Employee Spotlight with David Schmitz, PE, Manager of Project Management

-

Panel Takeaways: The Keys to Clean Energy Resilience

-

Leadership Moment: Kurt M. Kisch, Senior Manager – Survey

-

Going Beyond What’s Expected: Mikayla Boche on Environmental Compliance and How We Can Do More

-

Leadership Moment: Ahmed Garad, PE, Technical Manager – Substation

-

Ulteig Joins ‘CEO Action for Diversity and Inclusion’

-

Why Long-Lasting, Trusted Relationships Will Bring Success to CDOT on I-70

-

Ulteig Top 50 Places to Work for 5th Year in a Row in 2022

-

Ulteig Appoints Abhi Shah to its Board of Directors

-

Leadership Moment: Mandi Spindler, Talent Director

-

Ulteig announces the promotion of Sarah Beckman, PE, SMIEEE to the position of Vice President – Power Market.

-

Faces of Renewables – Celebrating American Clean Power Week

-

Ulteig Defines Valuability: A New Term for Creating and Measuring Value Across Lifeline Sectors

-

Ulteig Fights Tight Timeline to Secure Environmental Permits and Improve Passing Lanes along U.S. 52

-

Employee Spotlight with Cassie Borden, Graduate Engineer – Civil

-

One Common Language: How Ulteig’s Advanced GIS Capabilities Are Revolutionizing Management of Lifeline Sector Projects

-

Tenacity Rules the Day for This Seasoned Woman in Renewables: Cynthia Christensen

-

Making Room for a Growing Wind Industry: Ulteig Oversees Construction Management of Colorado’s Highway I-76/CO 52 Intersection

-

Vanessa Victor featured in Roads & Bridges Magazine

-

Board Chair Receives Outstanding Director Award 2022

-

Employee Spotlight: Randi Sue Surratt Changes Lives, Strengthens Communities Implementing Renewable Energy Infrastructure in Texas

-

Women in Engineering Day 2022

-

Water Project Replaces Aging Water Infrastructure for Small Minnesota Town Known for Walleye and Musky Fishing

-

Ulteig Named in Top Workplaces by StarTribune 2022

-

NERC Doesn’t Have to Mean Overworked

-

Ulteig Named on Zweig Hot Firm List for 2022

-

Ulteig to Lead Renovations for Colorado’s Iconic Eisenhower-Johnson Tunnel

-

Ulteig in Top 10 2022 Firms by EC&M

-

2022 Denver Top Workplace

-

What’s Next in Solar, Part 2

-

Josh Guck named RMEL Emerging Leader

-

Grid Modernization Experts at Ulteig Say Strategic Undergrounding is Next in the Evolution of Electrical Reliability and Safety

-

Staying Safe this Wildfire Season

-

Andi Schmid and Aaron Lauinger are ‘AEC Industry Rising Stars’

-

Ulteig Ranks in Top 500 ENR Design Firm List

-

Ulteig Announces New Power Market Director

-

Ulteig Employee Spotlight: Morgan Allaby

-

Repairing a Deteriorating Bridge Pier on an Aging Bridge in North Dakota

-

Andi Schmid wins Top Honor

-

Ulteig Helps Small Town in Iowa Struck by Devastating Floods Build Back its Water Supply

-

What’s Next in Solar Part 1

-

Prairie Business Magazine Honors Ashley Campion

-

Ulteig Employee Spotlight: Eric Amaya

-

Ulteig Names Nick Ingolfsland as Chief Innovation and Technology Officer

-

Ulteig Named as a ‘Best Place for Working Parents’

-

Ulteig Noise Modeling Experts Help Clients Create Better Dialogue with Local Communities, Optimizing Project Performance

-

Powering up a Substation Design Career

-

Americans are Ready to Buy EVs, But are America’s Utilities Ready to Power Them?

-

In the Cowboy Capital of the World, the Buckthorn Wind Facility Heralds a New Age of Renewable Energy

-

Ulteig Exceeds Expectations in Renovating Historic Lewis & Clark Expedition Route in North Dakota

-

Ensuring Safe, Reliable Electricity for Generations to Come: Ulteig Helps Redding Electric Utility Build a 10-Year Grid Modernization Plan

-

Senior Right-of-Way Specialist Lisa Brekkestran Brings Expertise, Compassion, and Trust to Her Role on Major Red River Valley Flood Mitigation Project

-

Leveraging the Power of GIS to Increase the Effectiveness of Infrastructure Design, Planning and Construction

-

Celebrating Veterans Day/Rememberance Day

-

Ulteig Energy & Infrastructure Podcast: Embracing a Changing Workplace Forever Altered by a Pandemic

-

Replacing a Water Treatment Facility

-

Embracing DEI to Enhance Ulteig’s Putting People First Culture

-

Bringing it All Together: Wind, Solar and Battery Storage in Northwest Ohio to Power General Motors

-

Celebrating Employee Owners

-

Teddy Rosamond Substation Offers a Template for Future, State-of-the-Art Solar-Powered Substations

-

Harnessing the Power of Wind-Rich New Mexico

-

Ulteig Reaches Impressive Safety Milestone

-

Defining what fuels Ulteig’s success begins with authentic leadership and a desire to continuously find better ways to solve client problems.

-

When it Comes to Transmission Lines, Bigger is Often Better

-

Ulteig’s 2021 Capabilities Brochure

-

Employee Spotlight: Opportunity to Develop Renewables Solutions Brings Devin Radovich to Ulteig

-

President Doug Jaeger Featured In Leadership Podcast

-

Ulteig Named to Prairie Business’ 50 BEST PLACES TO WORK Fourth Year In A Row

-

Ulteig wins National Cultural Excellence Awards

-

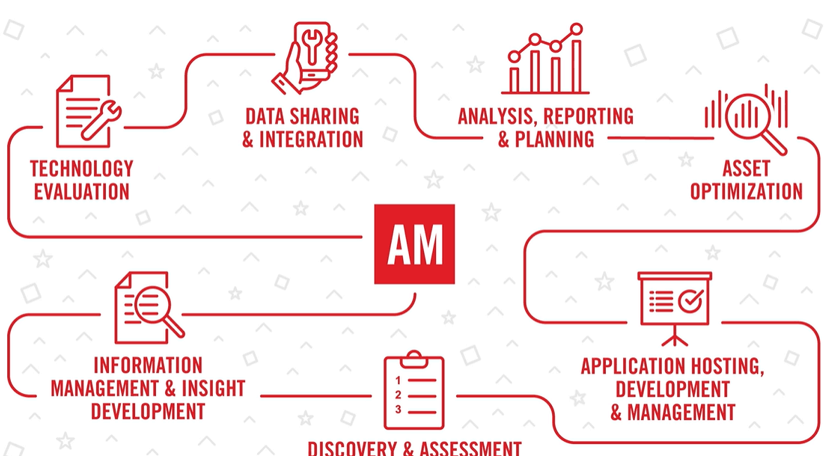

Asset Management Helps Organizations Mitigate Risks and Better Plan for Tomorrow

-

How COVID-19 Impacted Bicycle Commuting in Denver

-

The Unsung Heroes of North America’s Towns and Cities: Water Treatment Professionals

-

Ulteig Energy & Infrastructure Podcast: Gen Z – Ready to Fix the World by Designing Better Infrastructure

-

Advanced Technology Center Fuels a Futures Mindset Culture to Help Clients See Around Corners

-

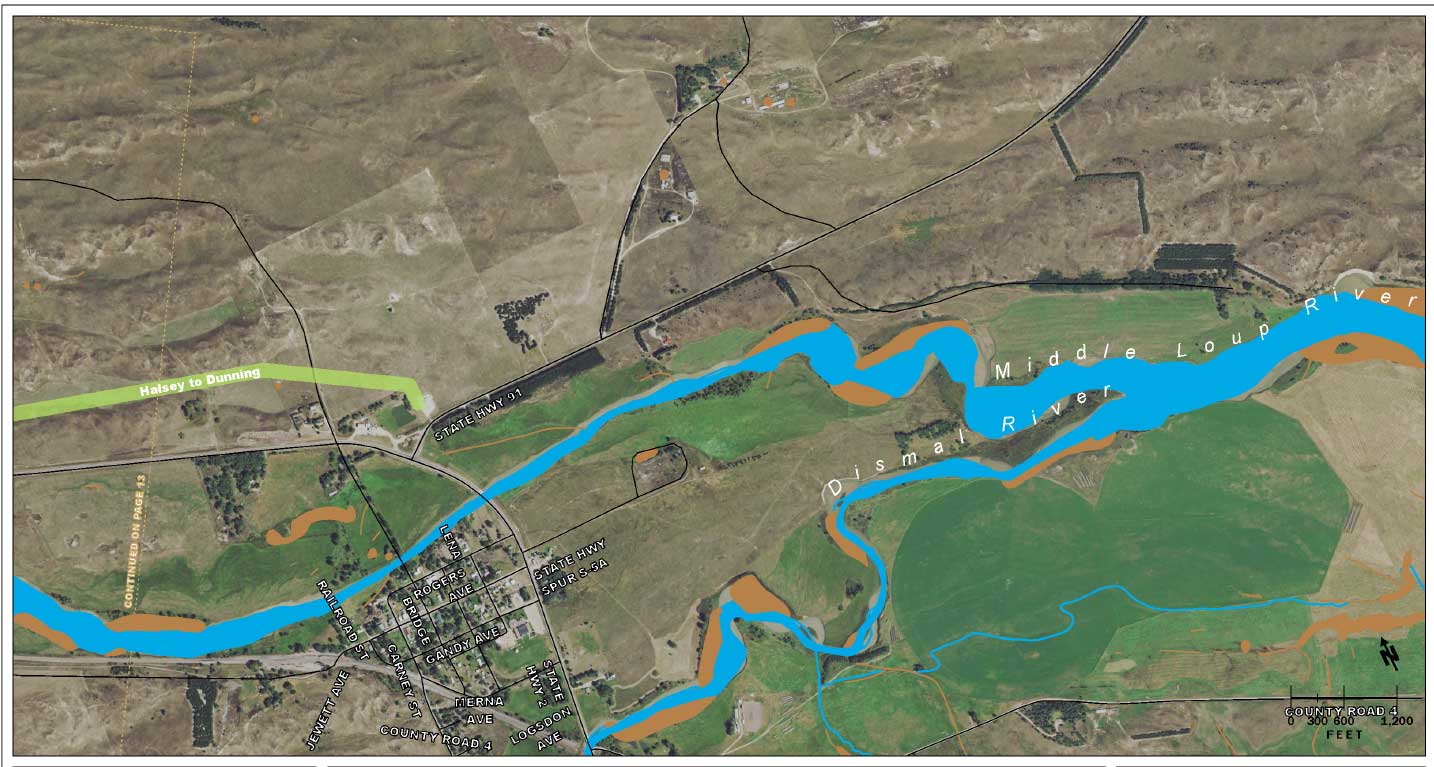

Creating Opportunities for the Future While Protecting the Sandhills

-

Celebrating Women in Engineering

-

Harvesting a New Crop in Iowa: Expanding Newport Substation Allows CIPCO to Interconnect with New Solar Farm in Wapello Part 2

-

Building Bridges and Connections: Relationships Bring Experienced Engineer to Ulteig and Building Connections Will Keep Her Here

-

Augmented Reality Technology Adds New Dimension to Infrastructure Design, Planning and Maintenance

-

Solar Power and BESS Integration in Oil Country

-

FERC 827

-

Hurricanes, Derechos, 500-Year Floods: Modernizing the Grid to Build in Resiliency and Hardening

-

Ulteig Names Ava Drayton as Senior Vice President, Client Solutions

-

Impact of Infrastructure Bill Launching a New Golden Age of Construction

-

International Women in Engineering Day

-

Ulteig is a Minnesota Top 175 Workplace

-

Ulteig Wins ACEC National Recognition Award

-

Celebrate National Right-of-Way Professionals Week: Ted Francois Shares Insights About the Critical Importance of Right-of-Way in the Development of Infrastructure

-

Prairie Business Features Doug Jaeger on NLS Acquisition, Company Growth

-

Ulteig Board of Directors Receives National Honor

-

Ulteig is #10 on Zweig’s Top 100 Hot Firm List

-

Ulteig Energy & Infrastructure Podcast: A New Sheriff is in Town

-

Ulteig’s Dave Bowen Receives RMEL’s 2021 Emerging Leader Award

-

Aiming Higher to Protect Endangered Species

-

Maintaining America’s Bridges on a Shoestring Budget

-

Project Delivery Services (PDS) Explained

-

Ulteig Acquires NLS Engineering, Expanding into Canada

-

Bring Harmony to your Wind or Solar Farm

-

A Passion for Small-Town Bridges in Texas

-

Never Underestimate the Power of Bridges to Connect

-

Unleashing the Power to Interconnect, Part 1

-

Ulteig Energy & Infrastructure Podcast: Exploring Alternative Construction Delivery Methods

-

Building connections: The Ulteig team engages stakeholders to benefit an entire community

-

Replacing an Aging Water Treatment Plant in the Red River Valley of Minnesota

-

Recent Texas Safety Regulation Serves as a Wake-up Call for Utilities Around the Country

-

Celebrating Surveyors Week: Jay Johnson Reflects on Years as Surveyor

-

Ulteig Energy & Infrastructure Podcast: Trends to Watch in 2021

-

Transmission Planning Takes a Futurist Mindset

-

It’s All about Flow: Ulteig Traffic Modeler Abdullah Kurkcu Takes His Passion for Data Science and Modeling on the Road

-

Modernizing Your Grid? Four-Stage Process Can Help Utilities Understand What’s Next

-

Ulteig Energy & Infrastructure Podcast: Renewable Energy in an Age of Change

-

Ulteig Energy & Infrastructure Podcast: On the Road Again – The Impact of COVID-19 on State Highway Systems

-

Increase Cost Effectiveness by Incorporating GIS Into Your Next Project

-

Utilizing GIS Technology for Field Based Distribution Design

-

Additional Evaluation in Preliminary Design Stage Can Reduce Costs and Keep Your Project on Schedule

-

The Future of Solar Development is Bright

-

Ulteig Energy & Infrastructure Podcast: What Does China Have to Do With America’s Power Grid?

-

Shuffling Panel Designs to Help Alleviate a Client’s Wire Shop Resourcing Issues

-

Ulteig Energy & Infrastructure Podcast: Where has the Tax Equity gone for Solar?

-

Ulteig Acquires Pacific Power Engineers, Inc

-

Ulteig Overview Video