Energy Storage Expertise

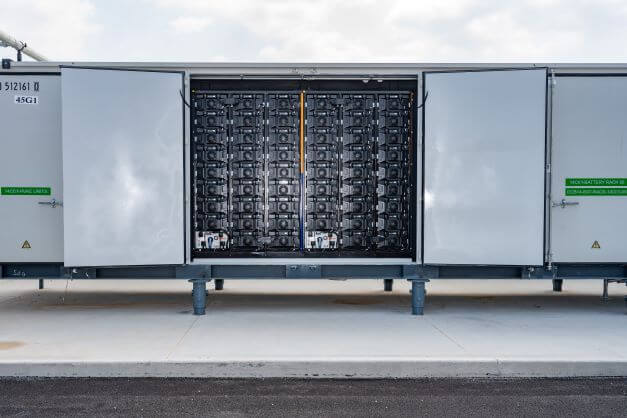

Based on significant experience in designing and engineering BESS projects, Ulteig was selected to design one of the largest battery energy storage systems to be built in Texas at the time of completion. The Battery Energy Storage System is a stand-alone 260 MW/260 MWhr lithium-ion system that consists of more than 3,000 individual battery modules. The system will bring instantaneous power to approximately 130,000 Texas residences on the Electrical Reliability Council of Texas (ERCOT) grid for one hour during times of increased energy demand.

The EPC contractor client selected Ulteig to design the BESS, as well as to provide permitting support, develop a Spill Prevention, Control, and Countermeasure (SPCC) report, and placing the location of a new on-site substation, which was engineered and constructed to connect the BESS with the existing natural gas power plant. Construction for the project began in June 2021 and was completed in May 2022

Innovative Solutions for Unique Challenges

Like any groundbreaking project, this one was not without its challenges. Obstacles that the Ulteig team encountered included:

Complex location for site-building – An existing ditch on the site plot, the presence of existing utilities on the power plant, and an atypical containment drainage system introduced complexity to the project’s civil and electrical design. Project engineers noted that the main drainage features for the east half of the plant originally ran directly through the project site, requiring the project designers to reroute the ditch to fit the new design.

Navigating an unpredictable supply chain – Due to worldwide supply chain disruptions, many lead times for equipment were longer than was standard for previous projects. To push forward with the project despite this obstacle, Ulteig engineers practiced flexibility in reworking their design to incorporate materials that were more readily available, ensuring timely completion of the project.

Optimizing Unconventional Backup Power Systems – In a typical power system, a local distribution line often serves as an emergency power backup to maximize grid resiliency. In the case of the this project, the local service did not have enough capacity to provide that function. This meant that the project’s source of emergency power would likely be changed throughout the project, necessitating a greater capacity for flexibility of the auxiliary power system. In addition to the BESS, the natural gas-fueled power plant also is backed up with generators supplied for seven days of power generation with diesel fuel.

“A decent amount of the decision to implement a diesel generator was risk profile,” said Tracker Goree, PE, Energy Solutions Engineer at Ulteig. “The key to resiliency is diversification. That doesn’t mean that the diesel generator is going to be utilized often or even ever. It might only ever turn on in the case of emergency, but regardless, it was necessary to implement to anticipate and overcome any risk.”

Put Your Project on the Map with Ulteig Expertise

To learn more about Ulteig’s expertise in energy storage, visit the Energy Storage page on www.Ulteig.com.