Grid Modernization Experts at Ulteig Say Strategic Undergrounding is Next in the Evolution of Electrical Reliability and Safety

May 6, 2022

Infrastructure Made Modern

In the face of wildfires, superstorms, and aging infrastructure, strategic undergrounding is being utilized to improve electrical reliability and safety, and reduce costs. Cost savings are achieved by reduced outages and vegetation clearing requirements, and replacing aging assets with low maintenance equipment.

As the potential threat of climate change and global warming becomes more evident, the near and long-term forecasts call for an increase of superstorms of greater intensity and more wildfires. These conditions, combined with an aging power grid means utilities in many parts of the country, big and small, are searching for new solutions to reduce their risks and manage costs while meeting their customer’s service and reliability expectations.

It’s here, at this critical juncture in modernizing the nation’s power grid, that Ulteig’s Grid Modernization engineers find themselves supporting investor-owned utilities, municipalities and power cooperatives in building more resilient power systems, beginning with a project for Duluth-based Minnesota Power.

Real Threats

In a world where electricity is increasingly embedded into our day-to-day lives, reliability is absolutely critical to today’s electric customers.

“Electricity is no longer a luxury; it is a necessity to live in today’s world,” said Ed Shannon, P.E., Senior Engineer at Ulteig. “People expect their lights to come on when they flip a light switch, just like they expect water to come out of the tap. This will continue with increasing reliance on energy for digital devices and internet access as work from home becomes the norm, demand for electric vehicles, and the trend of replacing natural gas systems with electrified heat sources in the next and beyond.”

However, utilities face real problems – vulnerability to superstorms, unprecedented flooding events and wildfires, which can compromise traditional above-ground distribution lines and lead to outages for customers. An Associated Press analysis of government data found that the number of outages tied to severe weather rose from about 50 annually nationwide in the early 2000s to more than 100 annually on average over the past five years.

“With the increase of extreme storms, utilities are beginning to recognize just how much money and resources they have spent on power line restoration within the past decade, the majority of which is replacing overhead infrastructure,” said Joshua Guck, P.E., Technical Manager at Ulteig.

According to the U.S. Energy Information Administration (EIA), utilities spent $57.4 billion on electric distribution in 2019, 6% more than the previous year and 64% more than they spent in 2000 after adjusting for inflation. The EIA also reported utilities’ distribution operations and maintenance (O&M) spending in 2019 totaled $14.6 billion, with $7.3 billion of that spent on overhead line maintenance including vegetation management and tree trimming; animal protection; line testing for strength, temperature, voltage and frequency; and repairs due to storms or faults.

Strategic Undergrounding for Minnesota Power Utility

Minnesota Power provides electricity for more than 145,000 residents and was experiencing similar issues to the industry with increasing cost of infrastructure restoration and vegetation management, as well as a high percentage of customers who didn’t want their trees trimmed or removed. Minnesota Power was also facing typical aging infrastructure and an increase in destructive storms, all leading to reliability concerns.

That’s when Minnesota Power sought out the expertise of Ulteig to provide a targeted solution in analyzing the best locations suited for converting overhead distribution lines to underground lines for better reliability of its power grid and offset O&M costs related to tree trimming and service restoration.

“A huge differentiator that utilities notice when working with Ulteig is we have multiple people on our Grid Modernization team that have spent quite a long time within distribution utilities and have gained experience from the Municipal, Co-op and Investor-Owned utility perspective,” said Guck. “Having spent that time with utilities and knowing what goes into their processes gives our team a very strong understanding of what utilities desire out of a project like this and allows us to anticipate and eliminate potential issues ahead of time.”

Quantifying Reliability

The process to implement strategic undergrounding for Minnesota Power’s lines began by determining exactly where and why the most outages were occurring.

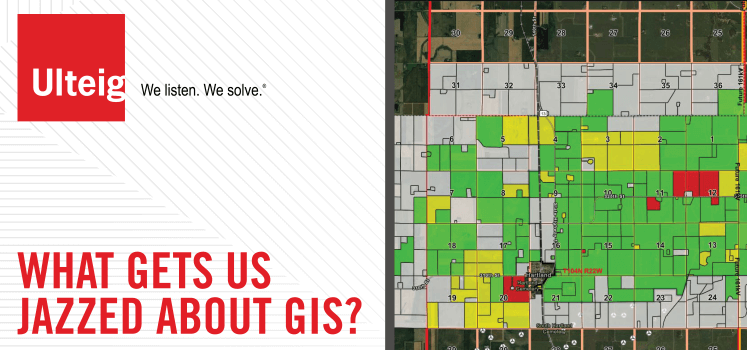

“First, we received as much information as possible from Minnesota Power’s data, such as their GIS system data, service territory maps, age of equipment, pole testing and reliability data,” said Shannon. “We then broke that data down to the feeder level and started selecting and sorting feeders based on numerous metrics, including reliability, asset age and asset health.”

To quantify the reliability of the existing system, the engineers used the following reliability definitions:

- ASAI – Average System Availability Index – This metric indicates how many hours electrical service was available to customers in relation to how many hours were demanded.

- SAIDI – System Average Interruption Duration Index – This metric determines the total duration of outages that the average customer experiences on the electrical system over the course of one year.

- SAIFI – System Average Interruption Frequency Index – This metric indicates how many outages the average customer experienced over the course of one year.

- CAIDI – Customer Average Interruption Duration Index – This metric quantifies the average amount of time that it takes a utility to restore service once it is lost.

After delving into the data, Ulteig identified feeders for review and began virtually patrolling the lines to gain a greater understanding of what is driving the reduced reliability in those areas.

A Targeted Approach Ensures Cost-Effective Project

Implementing strategic undergrounding can be a massive undertaking. That is why the engineers located and targeted which lines were the best candidates for strategic undergrounding, so the project could move forward in a cost-effective manner.

“Based on our review, we identified the areas where there would be the most benefits to switching those lines underground,” said Shannon. “We then quantified those factors and we scored them in eight categories.”

Those categories are as follows:

- Existing infrastructure age

- Potential reliability impact

- Distance from service center

- Existing underground status

- Operational cost savings

- Vegetation management

- Impact accessibility right away in terrain

- Overall project effort

Engineers also prioritized projects based on estimated projected project costs. This allowed them to identify which projects would be the least costly to undertake, so the utility could bring those projects to the front of its agenda (the “low-hanging fruit”), saving it money as it moves through the renovations.

In the end, Ulteig identified a total of 220 projects which included approximately 108 miles of primary lines and 57 miles of secondary lines for strategic undergrounding. From there, our engineers created a priority list of 50 projects that would maximize the most value for the utility and provided suggestions for which projects should be undertaken first. It was determined that if all 220 identified projects are completed, Minnesota Power could see O&M cost savings of approximately $1.7 million, with about $700 thousand of that in savings after completing the top 50 priority projects.

“A lot of utilities want to take a cost-benefit approach. Investor-owned utilities (IOU’s), in particular, typically need to present their spending recommendations to a state utility commission to get approval to finance those projects,” said Guck. “With all the improved benefits from undergrounding and identifying those strategic locations, it shouldn’t be a difficult task at all to get that financially approved by the commission.”

Implementing the Plan

Ulteig’s initial assessment of Minnesota Power’s grid was finalized in February 2022. The next step for Minnesota Power is to send out bids for the implementation of their recommendations. Engineers anticipate that the utility will be implementing all of Ulteig’s recommended projects over the course of the next seven years.

“Minnesota Power will see an improvement in their operating costs after implementing the strategic undergrounding of their grid,” said Shannon. “

Because the utility will experience significantly fewer outages after the renovations are implemented, when the utility does have an outage, their employees can locate the outage and service it faster and better than before.

Utilities: Gather Data, and Do it Now

If there is one piece of advice that the engineers at Ulteig would share for utilities seeking to increase their reliability through strategic undergrounding, it’s that data is key.

“If you’re not doing it now, start collecting reliability data as granular as possible,” advised Guck. “That information is extremely valuable when doing an assessment of this scale and importance.”

Their second piece of advice? Don’t wait.

“Operation and management costs are rising at a tremendous rate, so there really is no time better than now to modernize your electrical grid,” said Guck. “The longer you wait, the more expensive it will be, . If you want to ensure reliability for your customers for years to come, start upgrading your system today.”

Ulteig is a Nation-Wide Leader in Modernizing Infrastructure

For more than 75 years, Ulteig has revolutionized infrastructure and provided top-tier expertise to utilities in need. Visit the Knowledge Center to read more about the innovative work that Ulteig is performing for power, renewables, transportation and water customers throughout North America. Visit the Grid Modernization page to learn more about how Ulteig is pushing the envelope of what is expected of reliability for utilities across the nation.

WHAT MAKES ULTEIG DIFFERENT?

From global energy producers to locally funded cities and private developers to government agencies, the clients we serve encompass a broad range of relationships and projects. Find out why Ulteig is a leader in the engineering industry.

Contact Us